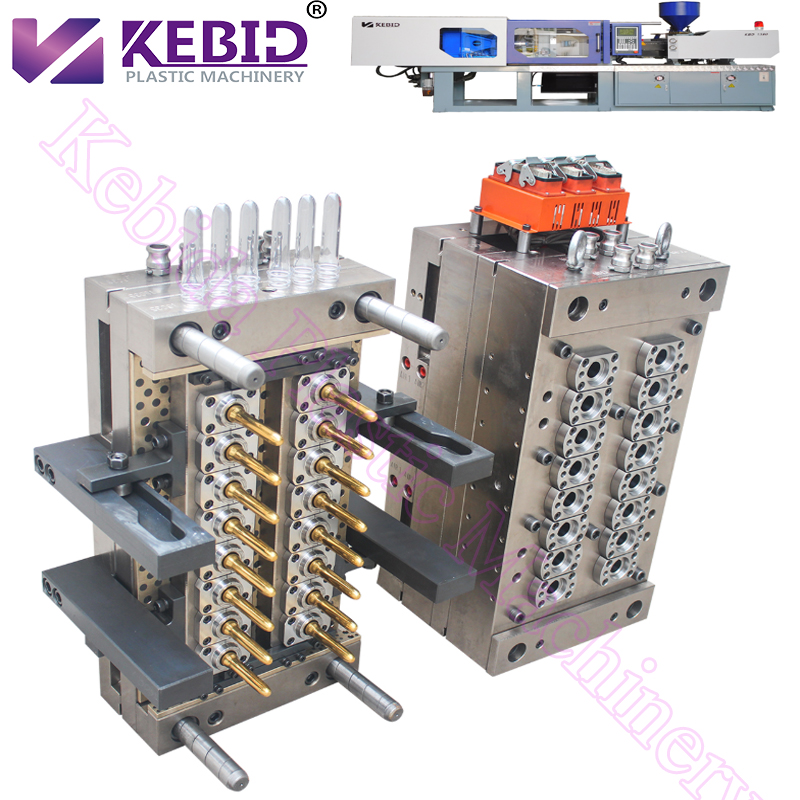

Self-Locking Short-Tail Pet Preform Mold

Description

Reviews

Ningbo Kebida(Hystan) Plastic Machinery Manufacturing Co.,ltd.located in beautiful coast of eastern sea, with 15 minutes to the international airport or high-speed rail station, very convenient to transportation, is a professional high-new technology enterprise, professionally manufacturing plastic injection molding machine. With dozens of years experience, have expected new factory of 10000 square.

Having led through the ISO 9001:2000 international quality management system certification and CE product certification, our company has independently developed and made the KBD series plastic injection molding machine, having the characteristics and advantages with beautiful appearance, strong calming force, high precision, low noise, energy saving and low consumption.KBD series energy-saving servo injection molding machine, PET preform special machine, high speed injection processing machine, high-speed machine, Bakelite machine, Resin special machine etc.dozens of series and kinds products has dozens of distribution networks and exclusive agents networks and after-sales services units in China. Products are far exported to Russia, South America, Europe and other Countries and Regions, having established sale network towards international market.

The pursuit of First-Class Quality Products is our company’s persistent objective, doing our best satisfy requirements of clients in domestic market and international markets, with constantly perfecting and pioneering sense of ownership, to create splendent and great future.

Q: How to choose injection molding machine?

A: The injection weight should be about 1.2× product's weight; The tie bar space should be bigger than the mold dimension; Contact with us for more information.

Q: How to pay?

A: 40% deposit T/T in advance, the balance 60% payment by T/T before delivery (we accept payment by T/T, L/C etc.)

Q: Is that possible for your company to send engineer to install machine for commissioning, even train our workers?

A: Yes, we can send our engineer to your factory for installing, commissioning, training. We have some engineers flying among different countries for after sale service and technical support. As per experience, if everything OK usually 5-15 days is enough. Therefore, before shipment, we need you to prepare invitation letter for visa. However, please be noted that all cost happened for visa, travel, hotel should be paid in advance by customers. In addition, we cannot guarantee each visa is successful.

Q: If we buy your machines, is there any warranty?

A: Yes, definitely. Totally 24-months warranty after shipment for mechanical parts, hydraulic parts, electric components (The screw just has 6-months). We are responsible for broken parts within 24-months. We will supply those parts in freeway but the possible transportation cost should be paid by clients.

Q: What is different with A,B,C screw, What is the price different?

A: The screw model is designed for different material and requirements, the screw diameter Changes from small, middle and big. There is no price difference in the price for choosing A/B/C screw types.

Q:How to choose the screw ?

A: For PC, Pa(Nylon)and other high viscosity material, it's better to choose A screw.

For PP, PE, PS materials, better to choose B Screw .

For Recycled material, better to choose C screw .

Q: What's the delivery preriod after place the order?

A: Normally the delivery date will be in one month after receiving the down payment .